I was impressed by PA0CMU's web site, and decided to build myself a CW key. My preferences were to have a single lever key (called "paddle"). Why exactly I wanted such type of morse key - don't know, it just looked more convenient to me.

My requirements for the project materials were:

- to use only cheap and easily accessible materials;

- to be manufactured easily without special tools/machines.

In addition, I wanted to extend PA0CMU's idea by:

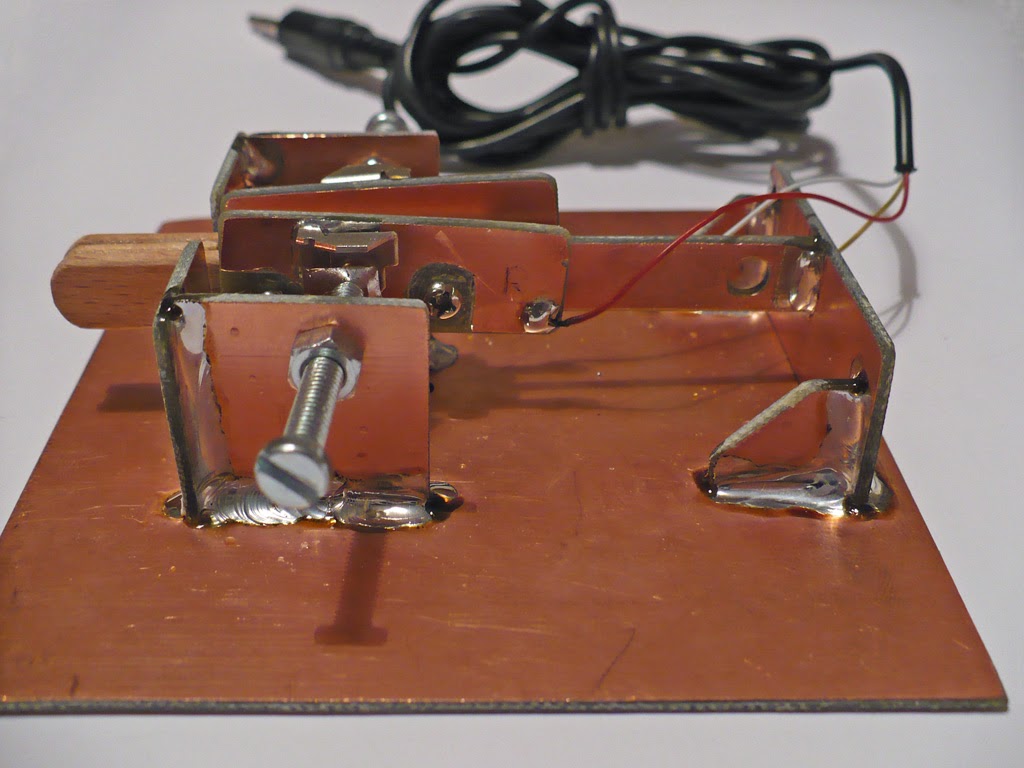

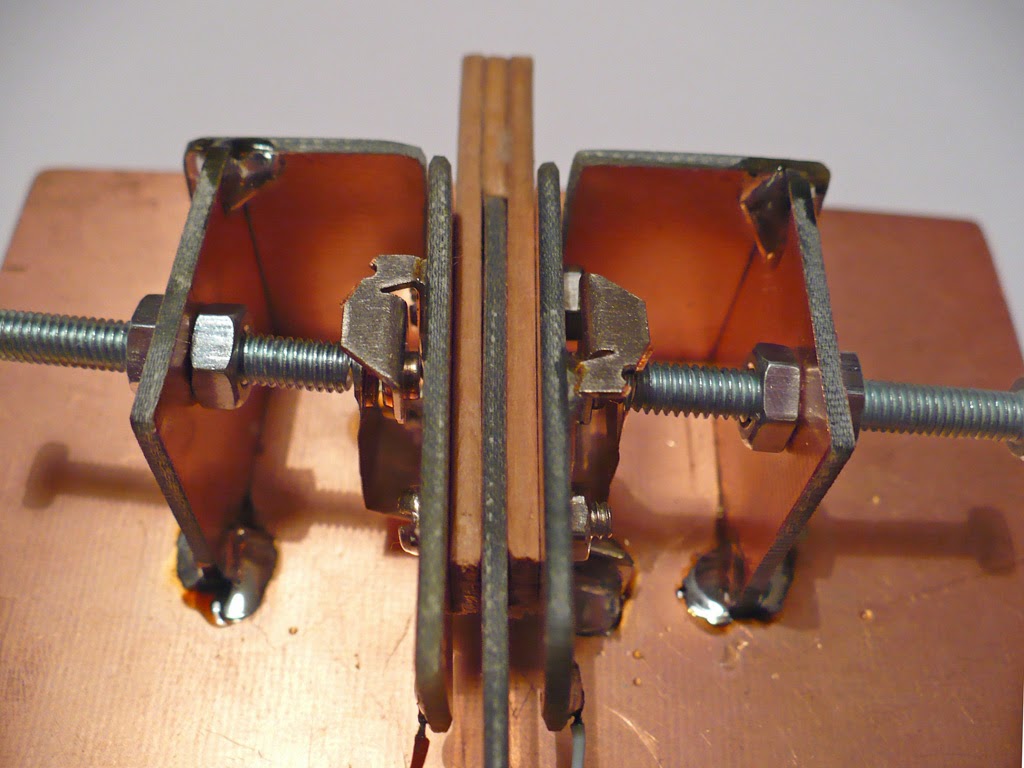

- prevent flexing the copper-clad board pieces by adding reinforcement pieces in the corners;

- using contacts from an off-the-shelf automotive relay, instead of screw and copper surface contact (it will oxidize sooner or later, as it's not protected);

- mounting a wooden handle, which is much pleasant for touching/using than the copper clad board.

So, here are my materials:

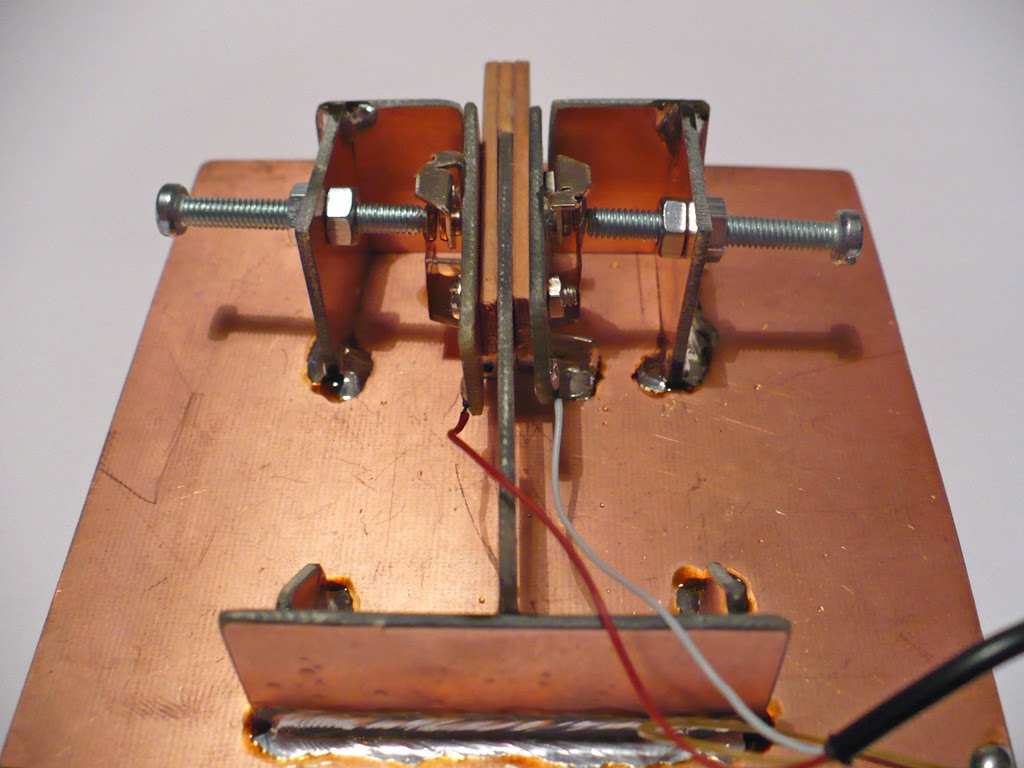

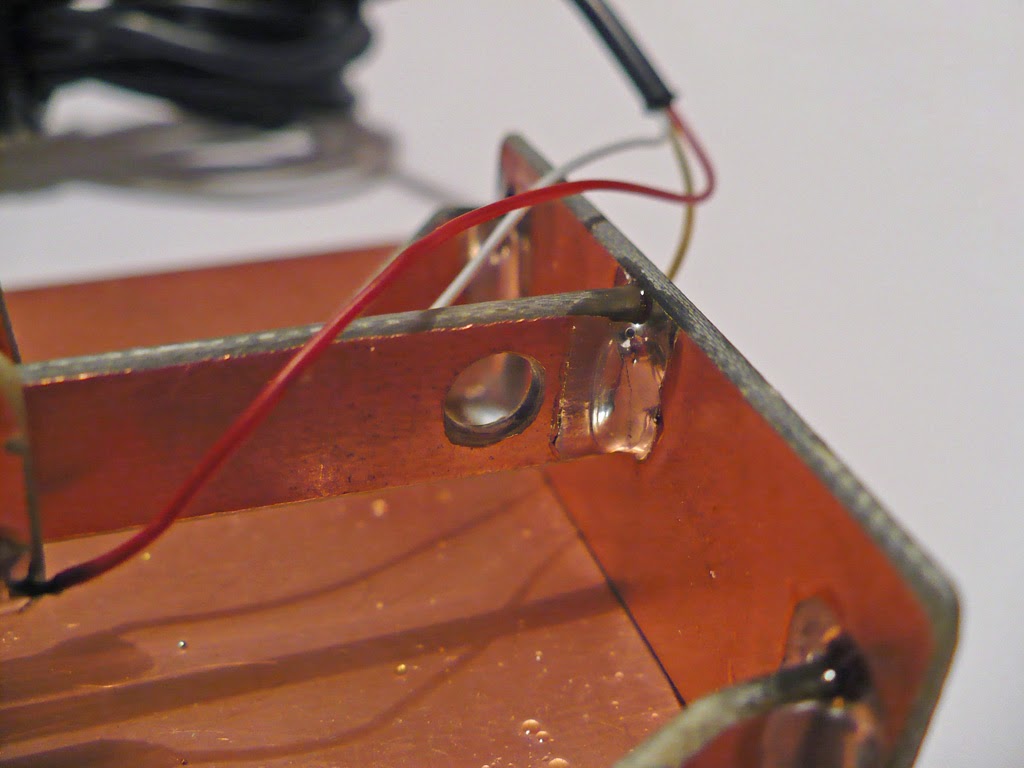

- double-sided copper clad (PCB). I just had that handy, and took advantage of soldering both sides for better mechanical strength.

- 2x low-cost automotive relays (Sun Hold SG4-1220A), used for their contacts (but probably any automotive power/high-current relay will do the job);

- 2x icecream sticks (for the key handle);

- cable + 3.5mm connector cut from old damaged headphones.

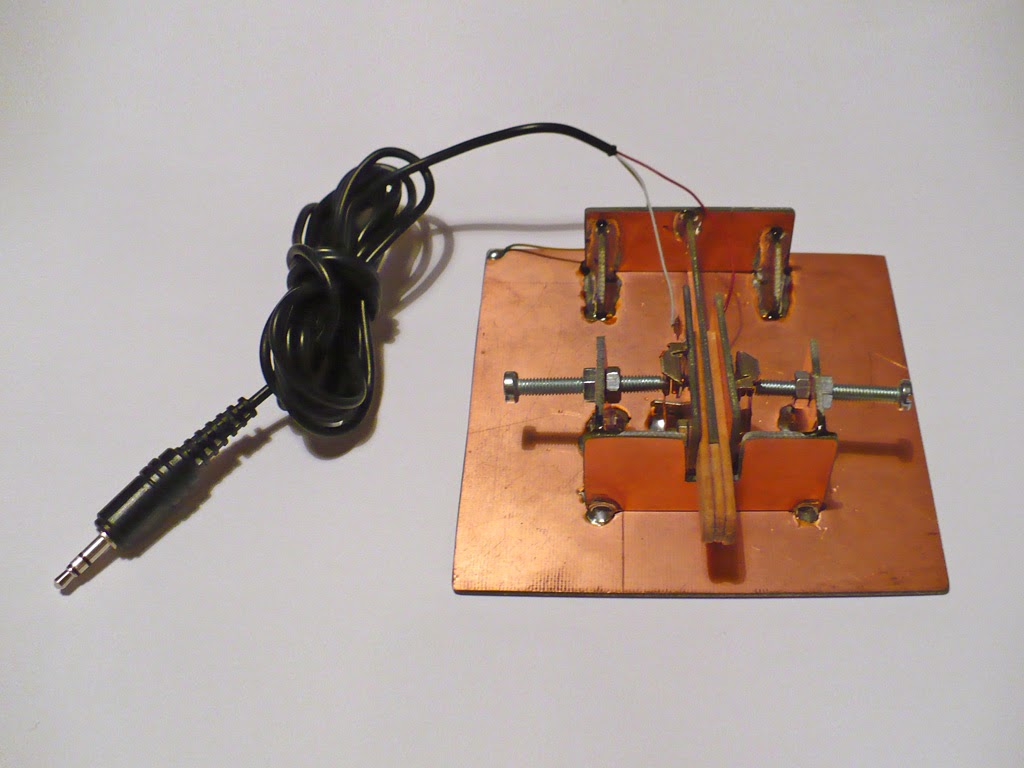

Here's a photo of my hand-made key together with the good old Icom IC-706 MKII:

I have to admit that I haven't planned for specific mechanical dimensions at all - I was just looking at PA0CMU's key and choosing materials/sizes which looked reasonable, and in the end I wanted to build this more key just for an hour or two. After I made the key I just rushed to connect it to my transceiver so I can try it and didn't bothered to properly fix the cable... but I'll have to do it anyway.

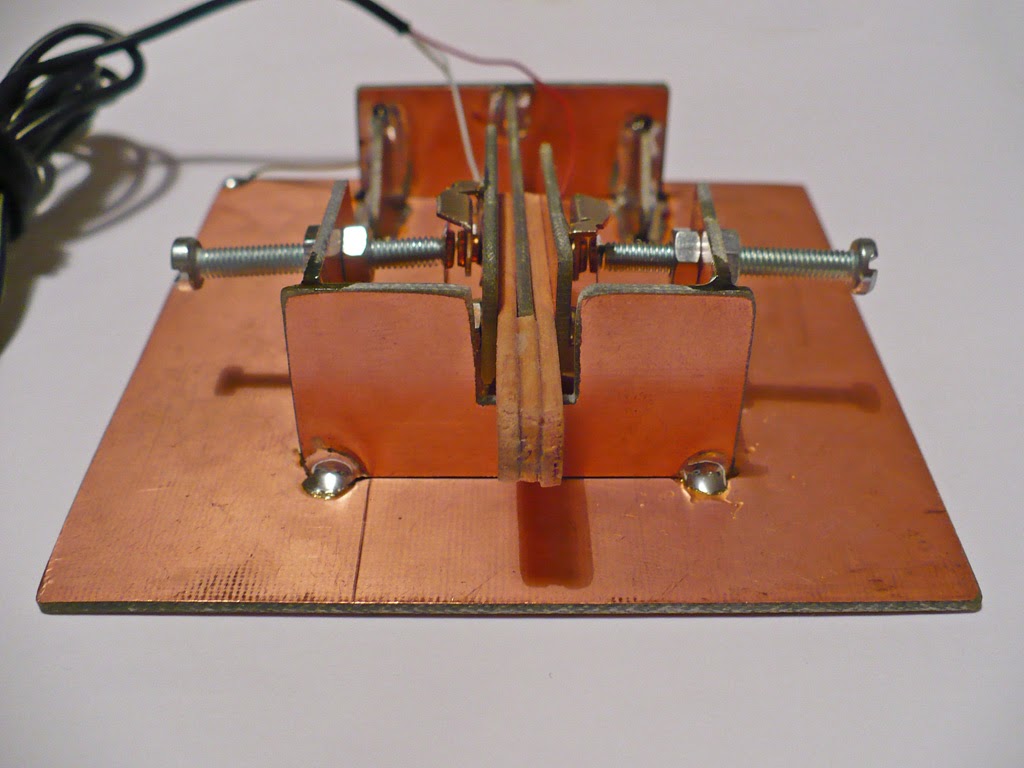

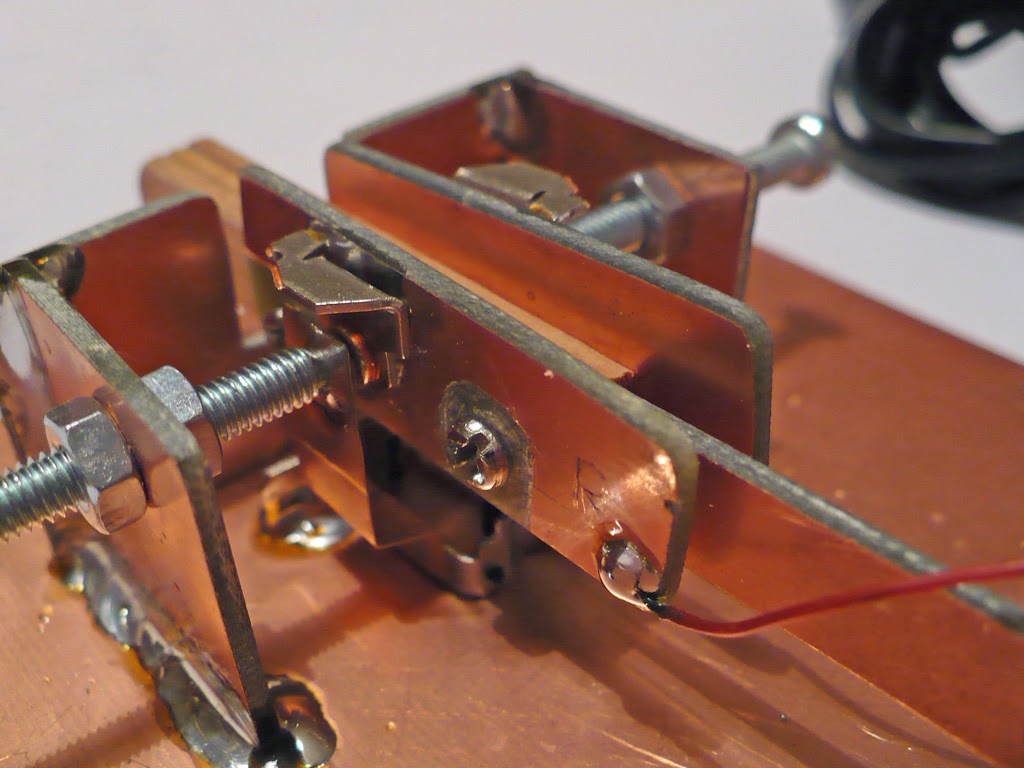

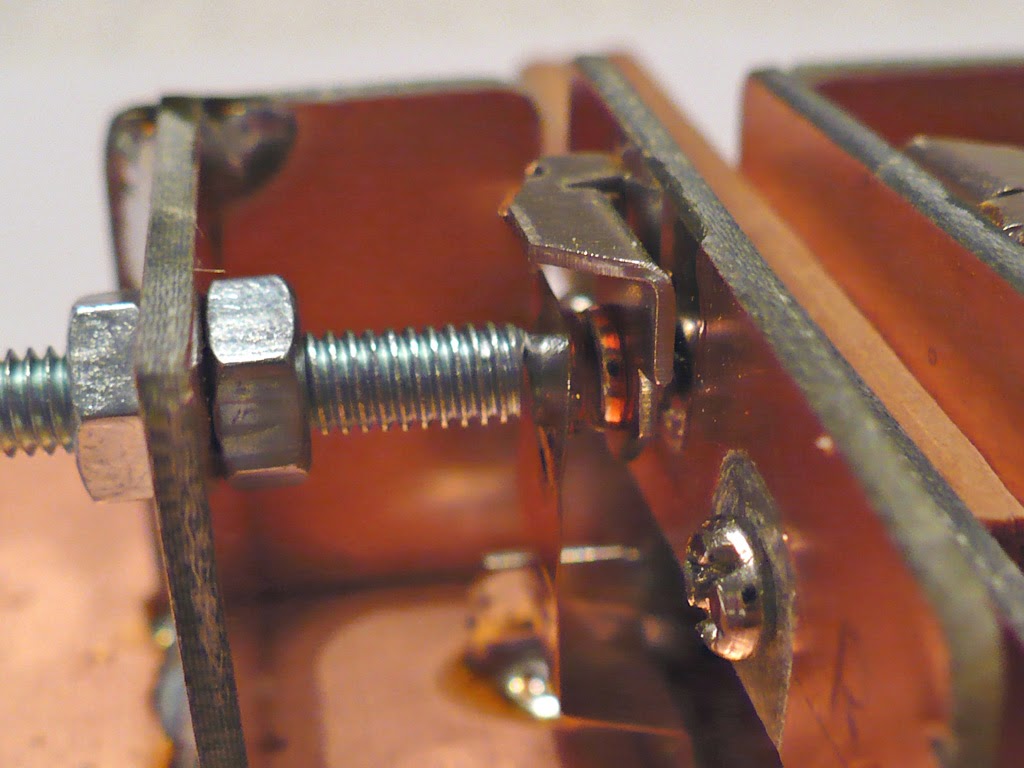

Here are more detailed pictures of the key:

Note that the screws are used to adjust the distance of side motion and to center the lever. The actual electrical contact is done by the relay pieces.

The original purpose of this hole was to make the material more flexible in this point. It turned out that it became too flexible, so it's up to you to decide how much lever flexibility is ok for you.

PS: This is an English translation of an original article of mine written back in Aug.2011.